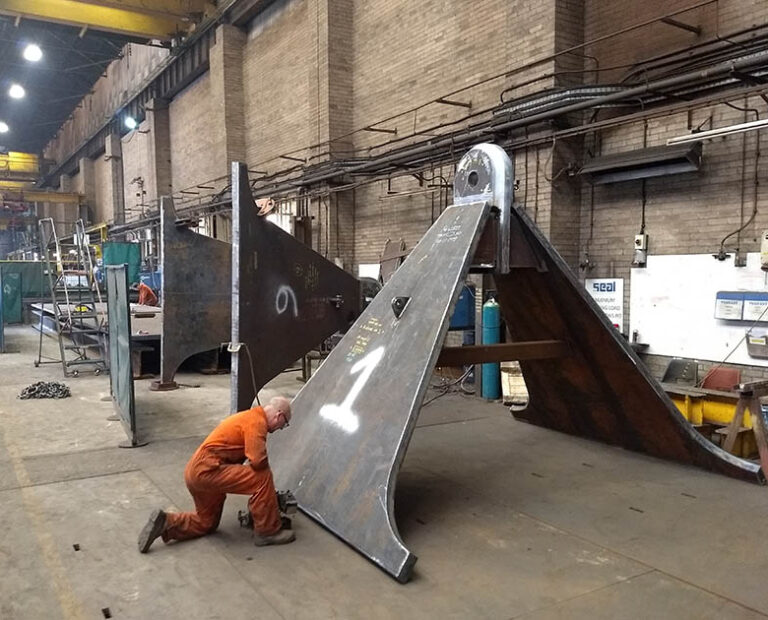

A patented innovation, the SEPLA (suction embedded plate anchors) is the unique combination of two proven anchoring concepts – suction piles and plate anchors.

At a significantly smaller size than a suction pile, the SEPLA manages to increase the anchor point efficiency of pre-set moorings and reduce mooring system costs for floating structures.

When introduced in 1997, the patented SEPLA system was a revolutionary concept in deepwater mooring. The combination of two proven anchoring concepts – suction piles and plate anchors – to increase the anchor point efficiency of pre-set moorings and reduce mooring system costs for floating structures.

With a proven track record in many regions of the world, from the Gulf of Mexico to West Africa and Asia Pacific, the SEPLA can be used for both temporary and permanent moorings. It is a particularly cost-efficient solution to anchor floating wind turbines.

Delivered by InterMoor

InterMoor is a world-leader in mooring technology, specialising in mooring assets from engineering and project management to provision of equipment to installation, inspection and repair.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

MOORINGS AND ANCHORS SOLUTIONS - REQUEST MORE INFORMATION

Acteon’s solid domain knowledge in mooring design and offshore mooring operations spans the globe. We have installed some of the largest offshore assets in all water depths. We provide an integrated service covering the entire project lifecycle, from engineering, mooring design, procurement, and installation, through to maintenance and decommissioning.

Similar products and services

-

Built from the ground up and free of legacy code, NavView combines a state-of-the-art...

-

Subsea articulating bearing systems are a cost-effective method of limiting peak loads...

-

A practical experience-based approach is considerably more valuable for a client than a...

-

Acteon's project management process is aligned with guidance provided in the Project...